From groundwork to AI: reinventing runway inspections

08 April 2025

For airport leaders, ensuring the safety and longevity of runway infrastructure is a constant challenge. Traditional inspection methods, while reliable, are labour-intensive, time-consuming and disruptive to airport operations.

However, a new wave of digital transformation–leveraging artificial intelligence (AI), machine learning (ML), and digital twins–is reshaping how airports approach pavement assessment and maintenance.

Engineering firm Alfred Benesch & Company (Benesch) is at the forefront of this change, collaborating with Bentley Systems–a developer of infrastructure engineering software–to revolutionise runway monitoring and pavement management.

The challenge of runway inspections

Airport runways experience considerable wear and tear, necessitating routine inspections to identify and assess cracks, spalling, structural weaknesses, and other surface issues. In addition to these concerns, it is equally important to evaluate the condition of runway signage, surface paint (such as markings and lines), and lighting systems.

This includes the identification, classification, and condition assessment of these critical safety elements. Traditionally, such inspections have been carried out manually, with personnel physically surveying runway sections, taking measurements, and extrapolating findings across the entire asset.

As Bret Tremblay, Technical Manager at Benesch, explains: “The current standard of inspecting sample sections and prorating the results is inherently inefficient and leaves room for uncertainty.”

And every moment a runway is closed for inspection translates to disruptions and potential revenue losses.

“When you’re on an airport, every moment that the airport is closed has operational concerns,” says Tremblay. “When it’s closed, they’re no longer taking inbound and outbound flights. So there’s potential revenue loss–whether it’s a commercial airline or a local agricultural airport, nobody wants to be down any longer than necessary.”

Recognising these challenges, Benesch sought a more data-driven, efficient and scalable solution.

Leveraging AI, ML, and digital twins

Benesch’s journey toward digitising pavement assessment began with their existing relationship with Bentley. They saw an opportunity to integrate Bentley’s iTwin technology with AI/ML capabilities to create an automated, data-centric workflow for runway monitoring. The approach is built around three core elements:

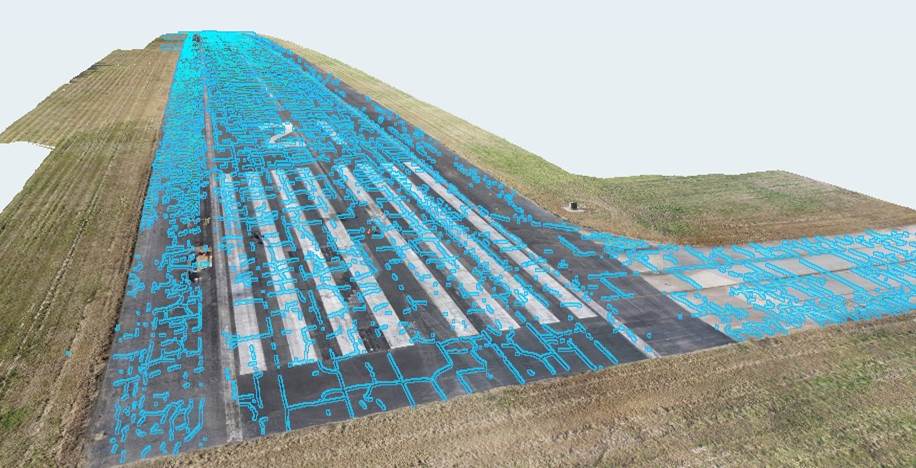

- Drone and vehicle-based data collection: High-resolution imagery is captured with minimal disruption to airport operations.

- AI-powered defect detection: Machine learning algorithms analyse imagery to identify and classify defects.

- Digital twin integration: Data is processed within a digital twin environment, providing a real-time, interactive model of the runway’s condition.

“We approached Bentley and said, ‘Hey, what if we could take photographs and extract crack data from them?’ Because we could then fly over an entire runway in less time than it takes to inspect a 100-by-100-foot grid sample section,” Tremblay recalls. “Then we’re no longer getting estimations–we’re getting actual quantities.”

This approach enables full-runway assessments rather than relying on sample sections, providing accurate defect quantification without the need for estimations or contingency buffers.

Field testing and real-world results

Benesch conducted extensive testing across multiple airports, refining the AI model and validating its accuracy against traditional inspection methods. One key pilot project took place in Georgia, where both manual and AI-driven inspections were conducted simultaneously. The results were striking: the AI-driven approach produced crack assessments within an 8-12 percent margin of the manual method—well within the 20 percent contingency typically applied to manual estimates.

Additionally, the implementation of AI/ML-driven inspections is projected to result in the following efficiency gains:

- A 75 percent reduction in manual fieldwork.

- A 90 percent reduction in CAD digitisation time.

- Estimated savings of US$144,000 for every 100 future airport inspections.

- A significant decrease in runway closure times, minimising operational disruptions.

“We had to make sure the AI-driven results were comparable to conventional methods,” says Tremblay. “If you’re asking someone to change their approach, they need to trust the data. We wanted to ensure that our digital inspection method could provide results that were within the standard contingency buffer of manual processes.

“The less time we need on the field, the safer the process becomes,” he continues. “By digitising the entire inspection workflow, we can perform in-depth analytics remotely, reducing human error and allowing for more accurate, defensible results.”

Additionally, the data collected through this process is not just limited to identifying defects.

“What’s really exciting is the ability to track deterioration over time,” Trembley notes. “We can now compare datasets year over year to see how cracks evolve, which parts of the runway degrade faster, and which areas need urgent attention. That means better predictive maintenance, smarter budgeting, and fewer costly emergency repairs.”

Addressing industry adoption and scepticism

While AI-powered inspections offer clear advantages, widespread industry adoption requires overcoming regulatory and operational hesitations. Tremblay acknowledges this reality.

“Airports and agencies need proof before shifting from traditional methods,” he explains. “That’s why ensuring our results align with the ‘golden standard’ manual process is critical.”

One significant hurdle is regulatory acceptance. Current FAA guidelines mandate manual inspections for certain assessments, limiting the extent to which AI-driven processes can be applied. Benesch is addressing this challenge by using AI to augment rather than replace manual inspections, paving the way for gradual regulatory evolution.

“Innovation breeds innovation,” says Tremblay. “Our initial goal was airport runways, but now we’ve got teams within Benesch adapting this process for bridge inspections. The technology is versatile and has the potential to redefine infrastructure management across the industry.”

However, adoption is not just about regulation–it’s about trust in AI itself.

“There’s always hesitation when new technology is introduced,” Tremblay explains. “People wonder, ‘How do we know the AI isn’t making mistakes?’ That’s why our priority has been ensuring that the results are as accurate, if not more so, than traditional methods. We’ve done side-by-side comparisons, and we’re proving that this system works.”

Future roadmap

Benesch and Bentley are continuing to refine the technology, with plans to enhance reporting functionalities and improve AI’s ability to distinguish between crack types, severities and depths. Additionally, by maintaining digital twins of airports over time, operators will be able to track pavement deterioration trends and make proactive maintenance decisions based on historical data.

“We’re working with Bentley to enhance how we report this data,” says Tremblay. “We’ve built the workflow–now it’s about refining how airports receive and interpret the results. We’re also looking at ways to use AI to classify cracks by severity, width and depth. The technology is evolving rapidly, and the better the sensors and cameras on drones become, the more precise our models will be.”

One of the most exciting aspects of the future roadmap is scalability.

“We started with runways, but this technology can be applied to any paved surface—aprons, taxiways, even roads and bridges. The ability to assess infrastructure digitally and accurately is a game-changer for asset management across the board.”

For airport executives overseeing technology and data, AI-driven pavement inspections represent an opportunity to enhance efficiency, reduce costs and improve safety. While challenges remain in terms of regulatory alignment and industry-wide adoption, Benesch and Bentley’s work is proving that AI, ML, and digital twins are more than just buzzwords–they are the future of infrastructure management.

With continued refinement and industry collaboration, the days of labour-intensive, sample-based inspections may soon be replaced by a smarter, more precise approach to runway maintenance, ensuring safer and more efficient airport operations worldwide. The ability to predict and prevent failures, rather than reacting to them, represents the next major evolution in airport asset management.

For more information about the Airports AI Alliance and how to get involved, visit: www.airportsalliance.ai.

Images: Benesch

Brought to you in partnership with: