How to balance construction and operations in today’s airports

02 October 2025

By Leif Johnson, Industry Solutions Director – Transportation at Bentley Systems

Airports never stand still. While millions of passengers pass through terminals and aircraft taxi on runways every day, behind the scenes a constant cycle of construction and maintenance is underway. From new terminal expansions and runway resurfacing to HVAC upgrades and retail fit-outs, projects of every size compete for space and time in environments where disruption can have an immediate impact on travellers and airlines.

The challenge for airport leaders is clear: how do you deliver essential upgrades and future-proofing while keeping day-to-day operations running smoothly? The answer increasingly lies in how effectively operations, maintenance, and construction are integrated–and how technology helps bridge the gaps.

Avoiding conflicts and disruption

Even relatively small construction projects in an airport environment can trigger complex knock-on effects. Closing a taxiway for resurfacing means flight delays and higher airline costs. Replacing an escalator at peak travel times can create bottlenecks and stress for passengers. Too often, overlaps between different projects or poorly timed interventions magnify these problems.

One example comes from a large US airport where two projects–HVAC works and a vendor installation–were carried out at the same time without a shared model or coordinated view. Only once construction was underway did the conflict between ducting and the new system emerge, causing delays, cost overruns, and frustrated contractors. It was not a failure of expertise, but of coordination and visibility–two things that technology is designed to solve.

One principle that resonates strongly is “bytes before bricks.” The idea is simple but powerful: simulate, model, and test digitally before anyone steps onto the construction site. Airports adopting modular approaches–such as building bathrooms off-site and installing them in place later–are already cutting downtime and improving passenger experience.

Simulation also extends to scheduling. Seattle-Tacoma International Airport (pictured) demonstrated this when installing a pedestrian bridge. Crews rehearsed the process virtually, then executed the lift during a narrow overnight window when the taxiway was closed. Within an hour, the bridge was in place and the taxiway reopened, all without disrupting air traffic. This level of precision is only possible when design, construction, and operations teams plan collaboratively with technology at the centre.

Guangzhou offers another instructive case. Facing major expansion works, the airport used virtual construction methods to model and rehearse activities before they began. This approach allowed the team to avoid demolition and costly rework entirely because potential conflicts were identified in advance. It also meant fewer workers were exposed to hazardous environments since the sequencing had already been refined digitally. The result was not just smoother delivery, but safer and more efficient operations throughout.

Technology as the bridge

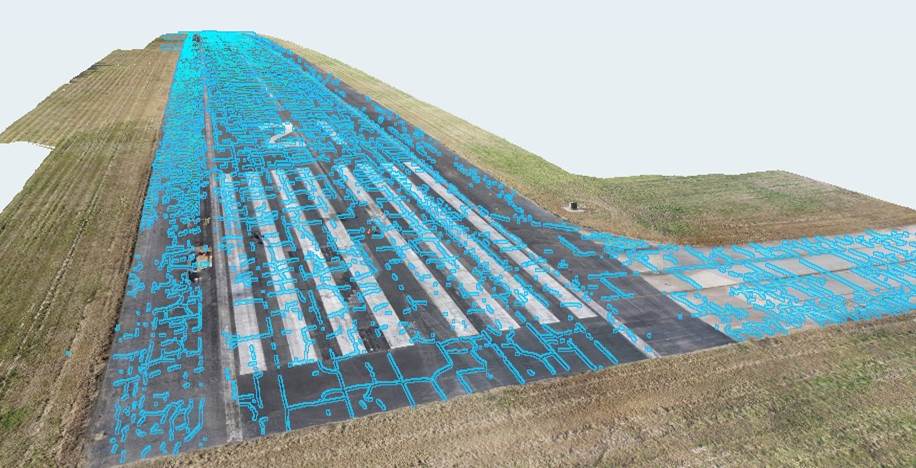

Digital twins have become central to how airports manage construction alongside operations. By capturing the existing state of infrastructure with tools such as reality modelling and LiDAR, airports gain a living, accurate record of assets. This allows construction teams to design in context, identify conflicts early, and simulate passenger movements or emergency evacuations before closing any part of a terminal.

For major projects like terminal expansions, digital twins provide visibility across multiple overlapping works, helping to avoid clashes and making it possible to adapt schedules quickly when materials are delayed or regulations change. The result is fewer surprises, less rework, and safer working environments.

While careful planning reduces disruption, unplanned failures still occur. Escalators break down, jet bridges need urgent repair, and lighting systems fail. The shift from reactive maintenance to predictive and preventative maintenance is therefore critical.

Sensors and Internet of Things (IoT) technologies now enable airports to monitor everything from oxygen levels in nearby waterways to the performance of runway lights. Combined with artificial intelligence, these tools can predict failures before they happen and schedule interventions during off-peak hours. Dallas-Fort Worth Airport already uses sensors to manage de-icing runoff and environmental impacts automatically–showing the wider potential of integrating AI into airport operations.

Planning for the future

Even the best planning cannot eliminate external constraints. Heathrow’s long-debated third runway illustrates how funding and technology are not the only hurdles–regulatory approvals and stakeholder concerns often shape what is possible. Here again, technology can help. By providing transparent, data-backed simulations of how projects will affect traffic, noise, and safety, airports can build stronger cases with regulators and communities.

Airports that successfully integrate operations, maintenance, and construction will be those that embrace digital-first approaches. The convergence of digital twins, IoT, and AI will not only improve efficiency but also enhance safety, environmental performance, and passenger satisfaction. These technologies reduce reliance on manual decision-making while ensuring oversight remains where it matters most–life safety and compliance.

The lesson is not that construction and operations will always be in conflict, but that they must be managed together as part of one system. Visibility across all projects, accurate modelling of existing assets, and proactive maintenance strategies are now indispensable.

Airports cannot afford downtime. Every disruption reverberates through the passenger experience and the wider aviation ecosystem. By embracing digital-first strategies, airports can transform the relationship between operations, maintenance, and construction from one of tension to one of synergy. The result is not just fewer delays or smoother projects, but a model of resilience that allows airports to grow, adapt, and serve passengers without losing momentum.

Main image: Port of Seattle